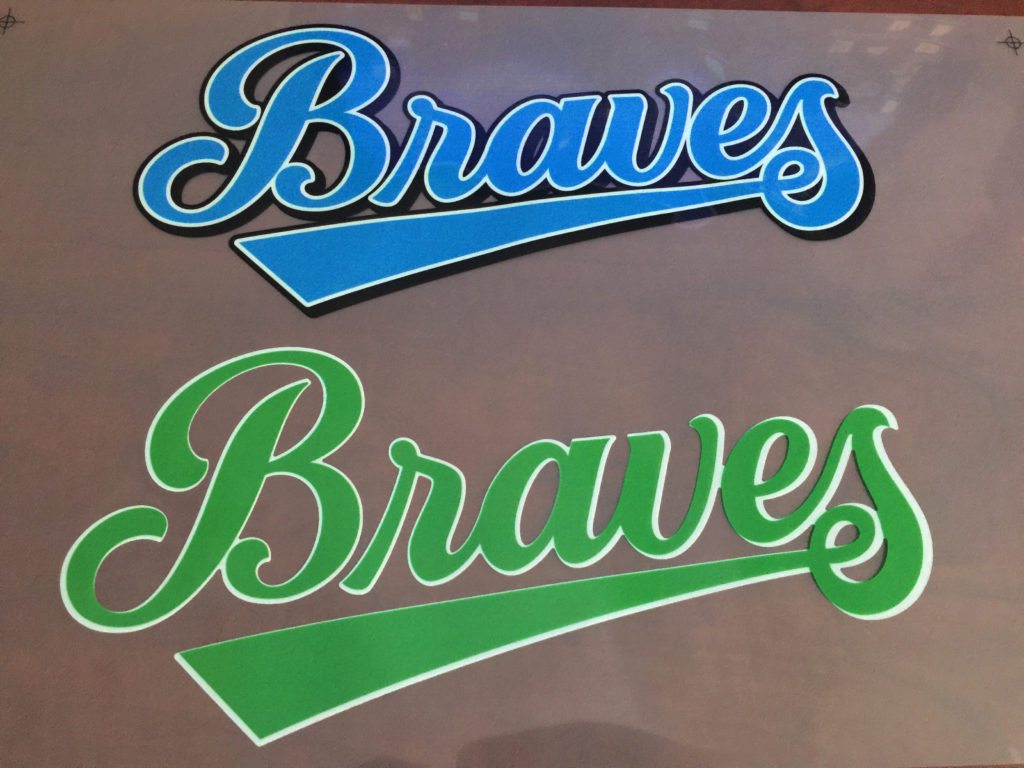

How to use Transfer Paper – Create a Gang Sheet

To get the most for your money using transfer papers you need to be familiar with what a “Gang Sheet” is. A “Gang Sheet” is simple a way to combine multiple images of the same logo or design one one sheet. When using the Digital / Screen printed heat transfers, you can even have multiple logos which are different on the same sheet. If you decide to go with spot color transfers, you can add different logos only if the logos contain the exact same ink colors. Using a gang sheet can be useful, especially if you have the need to print a crest print logo on the front of your shirt along with a full sized back logo. Gang Sheets can also be very cost effective when you have several small images which can fit many logos on one sheet. The more you can fit on your sheet, the lower your unit cost will be. When ordering a gang sheet you should consider the following:

- Determine the “Live area” of your sheet

- Allow enough room to cut your sheet

- Know exactly how many prints you will have using the minimum order

- Be sure to know how long it takes to cut apart your images

- Be careful not to smudge or scrape off ink when handling the paper