Glossary of Heat Transfer Printing Terms

This article provides a glossary of the most common heat transfer printing terms used by several custom heat transfer manufacturers, including BestHeatTransfers.com

Application Instructions – refers to how a custom heat transfer is applied to fabric or garments, which may be printed with a heat press machine or home iron-on. Instructions may include dwell time, heat press temperature and heat press machine’s pressure.

ADOBE ACROBAT – a program, which reads and saves Adobe Acrobat “PDF” files which stand for portable document file. Acrobat .pdf files can be viewed across multiple platforms including Microsoft Windows or Apple Macintosh computers.

ADOBE ILLUSTRATOR – Adobe Illustrator is a vector based drawing program which allows you to create print ready vector files which can be saved as .ai or .pdf or .eps to produce artwork for custom heat transfers, digital heat transfers, sublimation transfers and more.

ADOBE PHOTOSHOP – Adobe Photoshop is used to create and edit photos and raster based or pixel based images and artwork. The program was originally created to enhance photographs, but now can be used for full color custom heat transfers also known as four-color process transfers.

ADOBE PHOTOSHOP – Adobe Photoshop is used to create and edit photos and raster based or pixel based images and artwork. The program was originally created to enhance photographs, but now can be used for full color custom heat transfers also known as four-color process transfers.

ART SERVICES- Art services refers to logos or artwork that requires a professional to provide services such as converting raster images to vector files or creating gang sheets or providing ink color mapping services for custom heat transfers.

BANDING – Banding is the visible stair stepping of shades in a gradient that can be found in screen printed plastisol heat transfers.

BITMAP- A bitmap image is formed by a rectangular grid of pixels. The computer assigns a value to each pixel, from one bit of information (black or white), to as much as 24 pits per pixel for full color images.

BLEED – A bleed is an extra amount of printed image that extends beyond the trim edge of the sheet of transfer paper.

CARRIER SHEET – A carrier sheet generally refers to the type of paper or film a heat transfer is printed on. This can be either vinyl print and cut transfers, inkjet or laser printed heat transfers or screen printed plastisol heat transfers.

CAMERA READY ART – This may be a somewhat outdated term but sometimes used when submitting artwork or logos which are clear and sharp enough to be digitally scanned and converted to a vector based piece of artwork for plastisol transfers or other print and cut film transfers.

Glossary of Heat Transfer Printing Terms

CLC TRANSFER – CLC is short for Color Laser Copier Paper heat transfers, which have a clear coating material which allows toner from a laser copier to adhere and apply to fabric when applied with a heat press machine.

CMYK – CMYK is Cyan, Magenta, Yellow and “K” is for Black. CMYK , the subtractive primary colors or process colors used in color printing also known as 4/C process or four color process. When dots of each color are layered over top of one another a wide range of colors can be created. Process color heat transfers use a different ink formula that spot color transfers.

COLOR CORRECTION – The process of adjusting a CMYK image to compensate for color saturation and provide as close to true color as possible.

COLOR PROOF – A color proof can be a virtual sample of a logo or artwork, which may be in the form of a printed color copy paper or a .pdf or Adobe Acrobat image.

COLOR SEPARATION- The division of an image into different color components which are first separated in layers using an artwork program such as Illustrator or Photoshop and then used to image an individual screen used in making screen printed plastisol transfers.

COLD PEEL – Cold peel refers to a custom heat transfer which is applied with a commercial heat press machine for a specified time and temperature and then allowed to cool off completely before peeling the transfer paper.

COLOR MATCH – Color match refers to matching a specified ink color to either a previously printed heat transfer or printed t-shirt or matching a color using a pantone color known as PMS color.

COMP – Comprehensive artwork used to present the general color and heat transfer size layout of a heat transfer or gang sheet layout.

CONTRAST – The relationship between the lightest color and darkest color areas of an image, logo or artwork in a heat transfer.

COVER SHEETS – Cover sheets refer to an extra piece of either heat transfer or Teflon cover used to sometimes hold down the custom transfer to the fabric when the upper platen raises and causes a vacuum effect. Cover sheets also protect the upper platen from staining when applying a sublimation heat transfer.

CUSTOM TRANSFER – A custom heat transfer is created with a customer supplied piece of artwork which is sized and created with custom colors or made to the exact specifications from the customer. A custom transfer can be made into a screen printed plastisol transfer.

DENSITY – The degree of opacity of a photographic image or heat transfer image as it appears on paper or film.

Glossary of Heat Transfer Printing Terms

DISTRESSED PATTERN – A “distressed pattern” is a layered image, which appears scratched or worn off which is placed on the top layer of an art file. The distressed pattern is created to make the graphic look old and worn.

DITHERING – Dithering is a process of specifying color to adjacent pixels in order to simulate a third color in a bitmapped image. This technique is used when a full range of colors is not available and is primarily used with spot color heat transfers.

DOT GAIN – Dot gain is an unavoidable increase in the size of halftone dots used in the printing process, due to characteristics of ink, paper and press. This increase in dot size increases the density of ink on the page and thus makes the printed color more intense and more prevalent in screen-printing vs. litho printing.

DRAWDOWN – In ink mixing, a term used to describe the ink chemist’s method of determining a color shade. An actual ink sample is supplied for critical color approval.

DWELL TIME – Dwell time is the referring to the amount of time a heat press machine platen is touching the surface of the heat transfer measured in seconds or minuets when applying sublimation heat transfers.

DYE MIGRATION – Refers to dye sublimation, migration and bleeding often associated when applying heat transfers to polyester material or fabric. The dye in the fabric sublimates or converts from a solid to a gas without an intermediate step of becoming a liquid. Under high heat press machine or oven temperature, the dye migrates into the ink layer, which results in the ink being discolored or “bleeding” of the cured imprint.

EPS – EPS or Encapsulated Postscript, a file format used to transfer postscript image information from one program to another. The file includes postscript code and a low resolution PICT representation of the image.

FOUR COLOR PROCESS – The use of Cyan, Magenta, Yellow and Black using transparent colors over one another to produce a wide variety of colors.

FOIL PRINTING – Foil printing is custom heat transfer option, which uses a special sheet of Mylar coated with a colored foil. The heat transfer process is a two-step process using one transfer imaged with a logo or artwork which is screen printed on to the paper using adhesive. Once you apply the heat transfer to the garment you allow it to cool and then place the foil shiny side up over the entire image. By pressing one more time the foil sticks to the adhesive and is peeled away once the heat transfer cools.

FONT – OUTLINES – refers to converting a “live font” to paths. Many computers have installed postscript fonts. If you send a file to a heat transfer business that

FONT – CURVES – See Font-outlines

Glossary of Heat Transfer Printing Terms

FULL FRONT PRINT – refers to a popular heat transfer size usually a square or rectangle sized to the maximum size of the heat transfer paper. Also Full Back is used to refer to a print of the same size, which is intended on going on the back of the garment.

GANG SHEET – A gang sheet is defined as using a custom heat transfer paper with multiple images of the same design or color placed on one single transfer sheet which can be cut apart by the customer.

GLITTER INK – Glitter inks are in the same family as metallic inks but differ by the size of the metallic flake used in creating the ink. Glitter ink must be printed through a lower mesh number in order to allow the larger glitter ink flakes to pass through the screen. Glitter Heat Transfers generally need a longer dwell time due to the additional amount of ink being applied to the heat transfer.

GRADATION – or also called a gradient is a smooth transition between black and white, one color to another or color and no color when printed with either a spot color heat transfer or CMYK or Four color process heat transfer.

GRAYSCALE – The depiction or range of gray tones between black and white. A grayscale monitor is able to display distinct gray pixels as well as black and white ones.

HALFTONE SCREEN – A pattern of dots of different sizes used to simulate a continuous tone photograph or artwork either in color or black and white.

HIGHLIGHT – The lightest part of an image (usually white and nearly white portions).

HEAT PRESS – A heat press machine is used for the application of a heat transfer or iron-on heat transfer. The machine has a platen, which is heated and controlled with a thermostat, and a platen to place the garment or substrate. Heat Press Machines can print screen printed plastisol transfers or sublimation heat transfers as well as color laser copier or CLC heat Transfers.

HEAT PRINTING PILLOW – A heat printing pillow is usually made of heat resistant material such as Teflon and contains heat resistant foam inside. The pillow is used to help with uneven surfaces such as zippers or seams to provide even pressure distribution.

HOME IRON ON TRANSFER – A home iron-on heat transfer is formulated to allow simple application using any standard household iron. The transfer does not require as much pressure, but bonds to the fabric by an added low temperature adhesive so the use of a heat press machine is not required.

HOT PEEL – refers to a custom heat transfer or stock heat transfer, which is applied with a heat press machine for a specified dwell time. The paper is pulled off immediately while it is still hot, thus the name Hot Peel Heat Transfers. All of the ink transfers off of the paper with a hot peel heat transfer.

HOT SPLIT – Hot Split heat transfers refer to the application of a heat transfer, which is peeled away while still hot. The hot split transfer inks leave some of the ink on the paper or splits from the paper onto the fabric.

HEAT PRINTING – Heat printing is a term, which refers to the application of printing a stock heat transfer, or custom heat transfer, which is applied with a heat press machine.

HEAT TRANSFER – Heat Transfer is short for Iron-On Heat Transfer which essentially is an image applied to a piece of paper by a digital printer, or cut vinyl or screen printed. The Heat Transfer Paper is then applied to a garment or fabric or substrate using a heat press machine or a home iron.

INTERCHANGABLE PLATEN – refers to a lower or upper platen on a heat press machine that can be removed and replaced with a specific platen size to decorate items, which can be in all shapes and sizes.

JPEG- Jpeg’s are image files which are short for Joint Photographers Experts Group which uses a set of standards developed by the group for compressing and decompressing digitized images with computers. Also known as .jpg files.

KERNING – In typesetting, subtracting the space between two characters, to be closer together.

KNOCKOUT – A shape of object printed by eliminating or (knocking out) all background colors. Contrast to overprinting.

LPI – (Lines per inch), A measure of the frequency of a halftone screen usually ranges from 55 – 200. LPI refers to the frequency of the horizontal and vertical lines of dots that make up the screen.

LINE WEIGHT – Line weight when referred to the printing industry is the measure of a line in Points within a drawing program. Usually for heat transfer printing a minimum line weight thickness may not be less than 1 point thick.

Glossary of Heat Transfer Printing Terms

LITHO TRANSFER – Litho transfers (Litho is short for Lithography) which is a heat transfer printed using an offset or digital imaging machine. The Litho transfer has a special adhesive applied to the back of the image, which allows the ink to transfer from the paper on to the adhesive when applied with a heat press machine.

LOW RESOLUTION – Low resolution refers to a raster or bitmap image with a resolution lower than what is needed to produce a clean clear image. Low-resolution images can appear pixilated or blurry after printing.

MASK – There are two primary types of masks in Adobe Photoshop or Adobe Illustrator. Layer masks and clipping masks. Layer masks uses values of gray to assign levels of the transparency to specific portions of a layer or group of layers. A clipping mask uses the transparency of one layer to define that of a different layer group of layers.

MATTE FINISH TRANSFER – A matte finish heat transfer is printed on a piece of paper which does not have a coating and produced a dull finish similar to a screen-printed t-shirt. Matte finish heat transfers also may have a softer feel.

METALLIC TRANSFER – A metallic custom heat transfer has metal flakes embedded in the ink, which produces a somewhat, shiny heat transfer finish. Most metallic transfers are offered in Silver Metallic Ink or Gold Metallic ink, but can be custom mixed in other metallic heat transfer colors.

MICRO FIBER – The term Micro Fiber refers to a particular fabric type, which may be made from polyester or nylon but can also combine Polyester with Polypropylene fabrics. In order to heat press on micro fiber fabrics a low temperature adhesive must be used.

MIDTONES – The range of colors or levels of gray between the brightest and darkest ones in an image.

MOIRE – A moiré is an undesirable image produced in printing when halftone screen patterns become visible. This can be caused when the screens are misaligned and also caused by the relationship of the dot size angle against the screen mesh.

MONOCHROME – A black and white display with no gray tones.

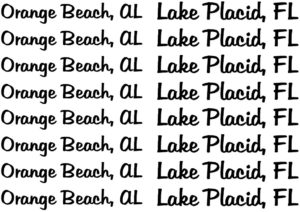

NAME DROP SHEET – A name drop sheet refers to a custom gang sheet heat transfer that is printed with a series of names or logos designed to be cut off and applied below a printed heat transfer. Many times name drops are used in the souvenir or resort t-shirt and gift markets.

NEGATIVE SPACE – When printing heat transfers negative space is referring to areas of the heat transfer that do not contain any ink. This can be in area such as the inside of lower case fonts where a minimum printing specification must be met before the transfer fills in causing the font to be illegible.

Glossary of Heat Transfer Printing Terms

OVERPRINTING – Overprinting is printing over areas which are already printed which is the opposite of knockout printing.

OPAQUE / OPACITY –The term opaque or opacity refers to how a solid color is applied to a garment or substrate allowing none of the fabric to show through the ink.

PANTONE – PMS COLOR – Pantone Inc, is a corporation best known for creating its Pantone Matching System also known as PMS, a proprietary color space used in a variety of industries, primarily printing which uses color swatches to promote unified colors during manufacturing.

PAD PROTECTOR – A pad protector is usually a Teflon sheet, which is affixed to a platen on a heat press machine. The pad, which is a heat transfer machine accessory, makes it easy to clean any heat transfer residue, which may unintentionally adhere to the platen.

PHOTO TRANSFERS – Photo transfers are custom heat transfers, which can be produced digitally to produce inkjet heat transfers or color laser copier transfers also known as CLC Heat Transfers. Photo transfers can be printed using a .jpg file.

PIXEL – a pixel is a minute area of illumination on a display screen such as a computer monitor of which many pixels together can produce an image.

PREFLIGHT ART – The examination of art before the art is produced o see if it qualifies for art specifications required to make a print.

PREPRESS – Collective terms for the steps necessary to go from the original artwork to output to printing plates or screens used to create a custom heat transfer or screen print.

PLATEN – A platen is the metal plate of a heat press machine used to sandwich a heat transfer by applying pressure either on one side or the other.

PLASTISOL – Plastisol is a screen printing ink which is based from a synthetic resin which is converted to a solid when heated to a minimum temperature of around 177 degrees Celsius. Many American Heat Transfer manufacturers prefer plastisol transfers because the inks do not dry out in the screens during the manufacturing process.

Glossary of Heat Transfer Printing Terms

PROCESS COLORS – Process colors are transparent and are not opaque unless a white under base is added. Process colors may also be short for Four Color Process, which uses Cyan, Magenta, Yellow and Black to create a multitude of color variations.

PRESSURE – Pressure is associated with heat press machine, which has a pressure adjustment, which can be changed to allow for different thicknesses in the material or substrate. Pressure is usually measured in PSI or Pounds per Square Inch.

PROOF – a proof refers to either an actual printed sample before a production run of a custom heat transfer. It may also refer to a digital proof or a virtual proof which is printed from a digital printer to offer an example of what the production may look like.

RASTER FILE – A raster file is a computer graphics image, which has a dot matrix structure, or a pixel based image.

REGISTRATION– The term registration in printing refers to the alignment of different films, screens or printing plates used to create one printed image.

RGB– RGB is short for Red, Green, Blue which is the additive colors used for a computer monitor or display.

ROSETTE – The pattern created when all four CMYK color halftone screens are printed at the traditional angles.

SATURATION – The measure of the amount of gray in a color. The higher the gray contents, the lower the saturation in the color.

SCREEN PRINTED TRANSFER – A screen-printed transfers using screen-printing mesh as a stencil to print on the surface of a carrier sheet such as paper or film. This is unlike digital heat transfers, which may not involve the use of any screens.

SPOT COLOR TRANSFER – A spot color transfer is a heat transfer printed with a solid pigmented ink. Spot colors are not typically transparent like CMYK transfers. Spot Colors are single ink colors that print on the transfer one color at a time.

SUBLIMATION HEAT TRANSFERS

Sublimation transfers also known as dye-sublimation transfers use ink technology designed to print on polyester coated surfaces such as apparel, signs,mugs, cell phone covers and other items. Sublimation works when heat and pressure are applied to a solid sublimation ink which causes a chemical reaction turning the ink to a gas without turning into a liquid. Due to the CMYK process the material must have neutral color in order to dye the substrate.

TEFLON SHEET – A Teflon sheet touch synthetic resin sheets which is resistant to heat and is sometimes used over top of a heat transfer or below the garment to prevent any heat transfer ink from damaging the garment.

TIFF – A tiff files stands for Tagged Image File Format, which is used to represent black and white, gray scale or color bitmap images, particularly those produced b scanners.

TRAPPING – A prepress technique that allows for variation of registration during the press run and is done primarily by allowing an overlap between abutting colors.

TRANSPARENCY– Transparency as related to custom heat transfers refers to either a layer in Photoshop with no color and has transparent colors atop of the layer.

VECTOR – A vector image uses programs such as Adobe Illustrator or Corel Draw to use pixels or small dots of squares of a color to create an overall image. This is unlike a raster file.

VIGNETTE – A vignette is an illustration, which the background fades gradually away until it blends into the unprinted paper on a heat transfer.